COMPANY

The Journey of ARK

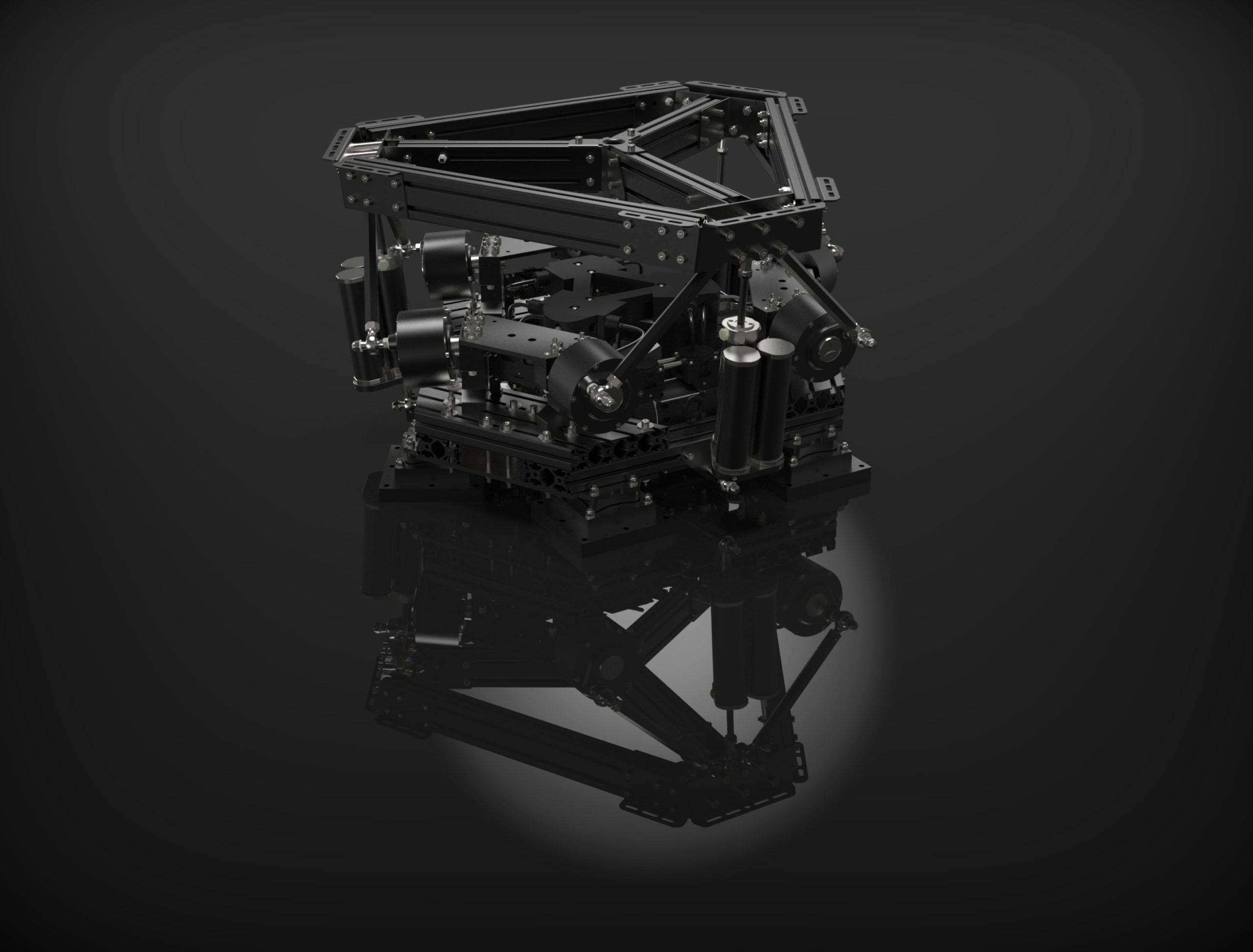

Employing a combination of innovative thinking, 3D printing, and the strategic use of bonding materials, we attached 14-bit encoders to the motors, transforming them into precision instruments capable of finely controlling the platform’s motion. Overcoming the mechanical challenges required extensive trial and error, but our persistence paid off.

The true test came when we sought to determine whether these six modified direct-drive hoverboard motors could levitate a person. By configuring them in a Stewart-Gough platform arrangement, we discovered the answer: they could!

However, success came with new obstacles. The motors began to overheat under the load. Once again, we turned to our inventive approach, incorporating gas struts manually pressurized to high levels. This compensation system worked, allowing the motors to hold a payload of up to 150kg stable in 3D space, levitating via magnetic fields without overheating.

But we didn’t stop there. We explored industrial automation to identify larger pneumatic pistons and creatively adapted them into programmable springs, outfitted with electronic solenoids, pressure sensors, a central manifold, and advanced coding.

As a result, the ARK platform became capable of supporting a payload in 3D space with minimal power consumption (around 15W) while instantly responding to external forces or user movements, only increasing power usage when needed to counteract these forces.

The next challenge was integrating game mechanics and motion cueing. With each step, we uncovered new opportunities and breakthroughs.

The culmination of our efforts, the ARK platform, represents a game-changing advancement in motion simulation, making this cutting-edge technology accessible to a wider audience.